12345678910111213141516171819

12345678910111213141516171819

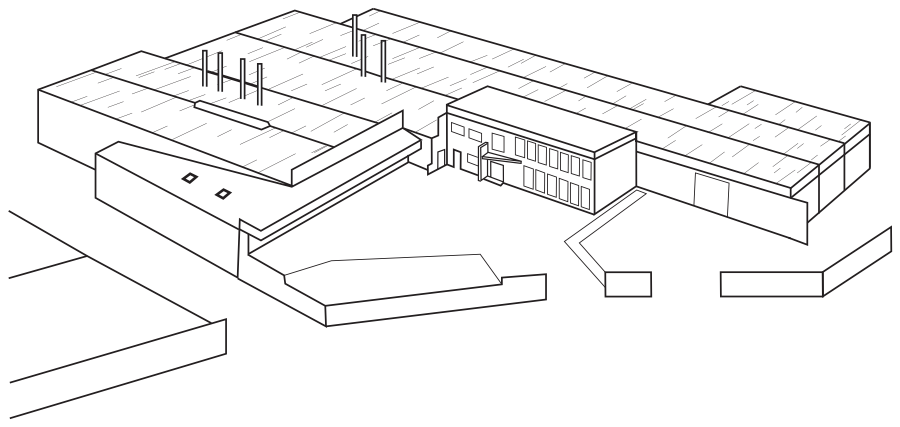

1 Administrative and social Building

This building is dedicated to the administrative and social departments. Here we can find the general & product direction, reunion room and our showroom.

2 Showroom

This area is dedicated to the exhibition of our collection, but also of the various exclusive projects we develop.

3 Finished product Warehouse

After finishing the products, they go to the warehouse where they are stored on pallets or boxes on order to be shipped. The shipping zone is attached to the warehouse so it’s easier to pack and ship the products.

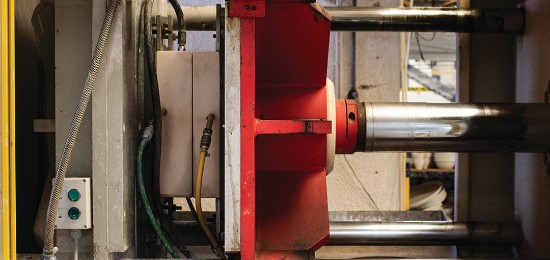

4 High pressure casting

This is one of the main technologies used in porcelain product making. By this mean we can have a bigger control of the shape and quality of the porcelain. This is also a good choice for large productions and simple shapes.

5 Decoration

Here is where the decoration of the products is done. Using the decal technique, we can personalize our products.

6 Raw products section

After forming, the pieces undergo a drying process in a controlled environment to lose excess water.

7 Casting section

In the Pottery section, this is where casting is made, such as the finishing of this product.

8 High pressure molds warehouse

Here are stored our high pressure casting molds.

9 Energy saving system

An energy saving device that reuses the heat from the oven to save energy.

10 Colour glazing section

This area is attached to the glass section. In this space, only colored pieces are enameled to avoid contamination.

11 White glazing section

In this section, the ceramic is merged in a solution of water and fine glass particles that form a fine coat all around the object.

12 Ovens

This is the process that finishes the production of the porcelain pieces. With a temperature that can reach the 1400ºC. This process helps to melt the glaze that covers the piece. As a result, we get a shiny and smooth finishing.

13 Handle casting section

Esta é uma secção especializada na conformação e no acabamento de asas de chávenas e canecas através de uma máquina de enchimento e secagem automática

14 Automatic Roller UF200

This is the section where the products are conformed using the roller technique. Various types of finishing’s are also performed here, including handle bonding.

15 Raw materials warehouse

This area is dedicated to the storage of the raw materials used to produce the porcelain paste.

16 Workshop / Maintenance

This attachment to our facilities allows us to have a quicker response when it comes to the maintenance of our equipment.

17 Solar panels

In order for us to have a product that is as sustainable as possible, reinforcing our commitment to the environment, we also have an area for the production of solar energy.

18 Conformation by roller

This space is dedicated to the roller conformation. There are 4 roller casting machines. Two of them with a diamenter of 20cm and another two with 40cm,

19 Product finishing - Roller

In this are there are two automatic finishing mchenes that allow us to finish the roller made products more efficiently.